COMPUTER SIMULATION OF ALLOYS PARAMETERS WITH L10-SUPERSTRUCTURE.

Valery V. Pivenj, Mikhail D. Starostenkov, Evgenya.V. Chernyh

Абстракт. Целью данной работы является построение парных потенциалов межатомного взаимодействия типа Морза для упорядоченных сплавов со сверхструктурой L1o. Построение включает как набор процедур с экспериментально известными параметрами сплавов, так и набор процедур с варьированными параметрами (значение тетрагональности (c/a); энергии сублимации; и др.). В сплавах PtZn, CuAu and TiAl получены ориентационные зависимости в соответствии с компьютерным анализом спектров энергий АФГ и учетом тетрагонального искажения решетки.

Abstract. It this work proposes subject of creation the interatomic interaction potentials of Morse’s type for ordered alloys with L1o-superstructure. This subject includes both collection of procedures with experimentally well-known parameters of alloys and collection of procedures which uncritical to parameters (tetragonality values (c/a); energies of sublimation; etc.) Orientation dependences were founded in accordance with a computer analysis of APBs energy spectrums in PtZn, CuAu and TiAl with accounting of the lattice’s tetragonal distortion.

1. Introduction.

The majority of properties of metals and alloys strongly depends on availability and quantity of various defects in a crystal lattice (Baurn N., 1970, Shtremelj M.A., 1982, Grinberg B.A. et al, 1985). Some properties are completely defined by imperfections of a crystal lattice, in particular, the physical and mechanical properties of alloys are strongly determined by planar defects, as a barrier for dislocation’s slip. Exactly the planar defects-superstructural, as antiphase boundaries, and structural, as packing defects,-in many respects define phisical and mechanical properties of ordered alloys. Twin boundaries render the main influence to structure and the properties in low-symmetrical superstructures and in high-symmetrical, especially cubic,-antiphase boundaries. However for interconversion of superstructures are claimed only antiphase boundaries (Popov L.E. et al, 1979, Kozlov E.V. et al, 1994). In particular, the crystal lattice of one superstructure can be transformed to other by various methods, and also by deformation of a stretching along a crystallographic direction. Nowdays there are many articles about structure of planar defects and deformed conversions in L10-superstructure, for example in TiAl (Paidar V., 1985, Kawabata T. et al, 1987, Wang W.K. et al, 1987, Feng C.R. et al, 1990, Girshick A. et al, 1995, Mahapatra R. et al, 1995).

As subject of research alloys with superstructure L10 were considered, which, as it is known, is tetragonal-deformed. An explanation of essence the given phenomenon are contained in work (Kozlov E.V. et al, 1994, Paidar V., 1985). At c/a ® 1.41 elementary cell of superstructure L10 is closer to fcc, and at c/a ® 1-to bcc. The majority of phases L10 are superstructures of a type CuAu, organized by a way of atom ordering in solid solutions and have wide areas of hases’ uniformity.

On the example of alloys PtZn, CuAu, TiAl, having various tetragonalities, and the tetragonal distortion increases from phase PtZn up phase TiAl. Energetics dependence of energetics of conservative antiphase boundaries from axial ratio (c/a) crystal lattice of alloys is considered.

2. Simulation.

The antiphase boundaries simulation includes three stages:

calculation of parameters for interatomic potentials in metals-components and in alloy;

b) construction the model crystallite with defects;

c) relaxation of atoms near the creating defect.

At deficiency of experimental data for description of potentials in indicated stages are reduced in uniform self-agreed algorithm and are executed iterationally until some given criteria will not be accomplished.

As semi-empirical function, describing central paired interatomic interaction in metals and alloys was given, potential function of Morse (Girifalco L.A. et al, 1959), having small number of adjustid parameters is considered:

![]() (1)

(1)

where r-distance between A and B atoms.

The Morse’s potentional parameters for alloys can be obtained from the system of equations:

(2)

(2)

where Eb-the complete binding energy of various atoms types in alloy, EAA and EBB-the binding energy of components, H-the formation heat of a solid solution, a-parameter of alloy’s lattice, B-module of 3-dimentional compression. If there is a whole set of the infoormation experimental items, the decision of system does not cause difficulties, however at the absence of values H, B or certain significance of tetragonality t =c/a, the system is incomplete and the listed significances can be found, for example, by variational algorithm. The algorithm of paired interatomic potential constractions for alloys was written. It solves the incomplete systems of equation, which are described above (2). Unknown parameters of equations are parameters of potential, a , b , D, and H, B and t are varied. The solution’s search of equations sistem (2) results in unique combination: 6 alloyed parameters and 12 parameters for metals-components, appropriate to a stable configuration of an alloy. The procedure for construction of model crystallite takes into account the following properties of defects and potential of interatomic interaction.

The size of a lattice in defect’s plane is such, that the plane contains a minimum quantity of atoms for 3-sphere approximation. The researched defects are such, that the atoms of all plane’s elementary cells are in equivalent situations and have identical neighbours. That’s why suffer from the equivalent effect and will undergo identical displacements in the result of relaxation. As to the size of crystallite at normal in the direction to the plane of APB, such criterion was used: edge planes on both sides from АPB should not contain the vectors of shift after relaxation-vectorial field wholly lays in the central part of crystallite. This value was carried out for each created defect, and when the question of the calculation’s time optimization of was not actual. It was accepted by the maximum in programm. The geometrical creation of planar defects, such as shift АPB in ideal crystallite was made by one part shift of crystallite relatively to another on Burgers vector (hkl).

- all the planes along the direction <hkl> contain atoms of two types with identical order;

- the elementary cell in plane contains four atoms - two atoms of each type, that’s why it exists two directions of shift, causing, however, the equivalent defects;

- in all the set of planes {hkl} the elementary cells with identical area can have two variants of filling by atoms and, that’s why, will form energetic various defects. The procedure of relaxation combines some properties of widely known algorithms of minimization, oriented to a specific class of problems, with elements of optimum programming and evident graphic representation of results. The basis of relaxation procedure is a gradient method. For local convergence’s of the given method, has appeared enough simple iteration with stored information about two last steps and gradient of one step. The submitted approach in the combination with the methods of discrete programming has allowed to reduce time of relaxation in comparison with classical gradient method more than one order, providing thus accuracy in displacement of atoms ~ 0.1 % of lattice parameters.

3. Results.

The parameters of Morse’s potentials were obtained for pure metal and alloy with several values of t in Table.

Table.

_____________________________________

Type of

interatomic

interaction, a , b D,

c/a (%) A-1 eV/at

_____________________________________

Pt-Pt |

1.57800 |

97.3175 |

0.736858 |

Zn-Zn |

1.51961 |

84.6111 |

0.166192 |

Pt-Zn (-1%) |

1.65670 |

104.2630 |

0.500038 |

(exp.) |

1.60458 |

92.4399 |

0.472184 |

(+1%) |

1.59453 |

90.0430 |

0.479193 |

(+2%) |

1.58210 |

87.2064 |

0.485872 |

Cu-Cu |

1.33728 |

41.5359 |

0.372392 |

Au-Au |

1.58302 |

114.7590 |

0.487709 |

Cu-Au (-1%) |

1.52670 |

80.6263 |

0.475450 |

(exp.) |

1.48072 |

72.2801 |

0.456740 |

(+1%) |

1.46815 |

69.9229 |

0.468280 |

(+2%) |

1.45845 |

68.0463 |

0.481930 |

Ti-Ti |

1.01884 |

26.3020 |

0.456210 |

Al-Al |

1.02448 |

27.1817 |

0.322360 |

Ti-Al (-2%) |

1.02448 |

26.7015 |

0.394696 |

(-1%) |

1.03129 |

27.0799 |

0.408785 |

(exp.) |

1.03465 |

27.2615 |

0.420763 |

(+1%) |

1.03990 |

27.5830 |

0.434712 |

(+2%) |

1.04716 |

28.0606 |

0.447889 |

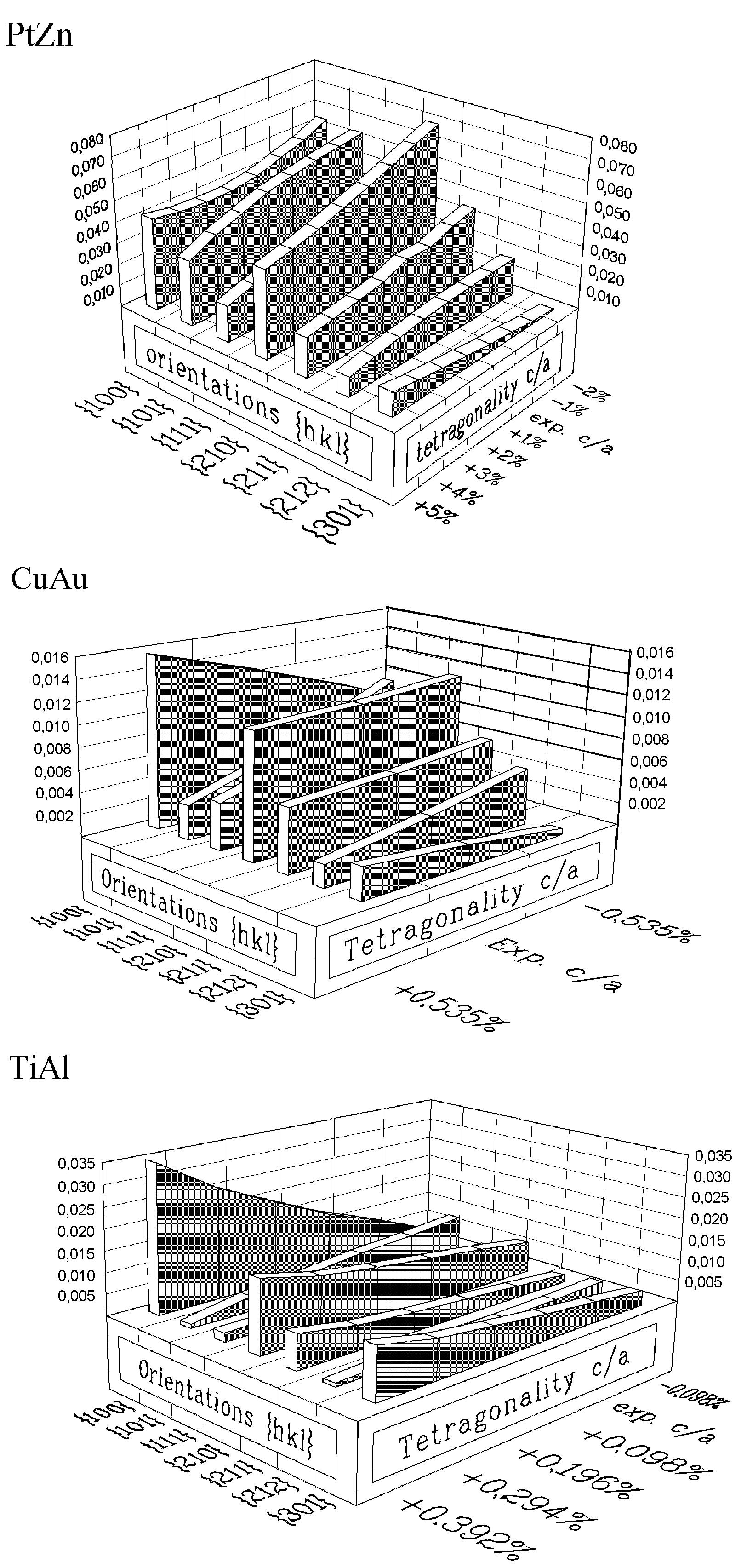

Fig.1. Orientation dependence of APB energies (EAPBx10, J/m2) from tetragonality for known magnitude of formation heat of alloys.

In this work are examined antiphase boundaries of a shift type in orientations {100}, {110}, {111}, {210}, {211}, {212}, {310}.

The research of АPB in chosen alloys was conducted in two directions:

- for known the formation heat’s magnitude of a solid solution the limits of tetragonality’ variation were found, including an experimentally known magnitude t for alloy (Fig.1);

- within the framework of offered model limits of tetragonality variation were found by variation of the formation heat. And as to the second direction heat H can be determined by variation t .

The criterium of approach consistency was the pictures of orientation distribution for energetic anisotropy. It is necessary to note, that one criteria in the given choice was the comparative spectrum analysis of forming energies distribution of different orientation’s defects. So for known magnitudes H and t in all choosen orientations {hkl} APBs creation is equiprobable process, and the probability is minimum.

4. Discussion

Figure 1 indicates orientation dependence of APB energies from tetragonality for known magnitudes H in alloys PtZn, CuAu and TiAl according to the first way of simulation. The limits of variation t have made for PtZn from -2 % up to + 5 % from known magnitude t ; for CuAu - from - 0.535 % up to +0.535 %; for TiAl - from - 0.098 % up to +0.392%. By reduction of lattice tetragonality in alloy PtZn, the reduction of considered faults energies in all orientations, except {100} and {301} is observed. The character of tetragonal dependence in orientation {100} presents interest: the minimum of APB energy is revealed at rather small tetragonal compression. In alloy CuAu the orientation anisotropy has similar character, however in orientation {100} the minimum of APB energy is not reached within the limits of change t . The character of orientation anisotropy in alloy TiAl much differs from results, received at modeling АPB in the previous alloys. Growing of APB energies is observed in {210} and {211} at stretching of a lattice. The limits reduction of tetragonal variation is observed in accordence with reduction of tetragonal distortion from phase PtZn to TiAl. The given process is accompanied by reduction of APBs energies at absolute values, except {301} (Fig.2).

The results of simulation recend by the second way are shown in Fig.3. The orientation dependence of APB energies from Hi and tetragonality t i are shown. The axial distortion limits of a lattice for each alloy are revealed. For PtZn the increase of tetragonal distortion has appeared to be impossible, and the reduction of distortion in the direction <100> has made about 10 % from reference value t . The increase of axial ratio is also impossible in alloy CuAu. In the opposite direction the deviation from known t is 7 % and has reached the ratio a=c. The change limits of tetragonality in alloy TiAl have made from -2 % up to + 2 %, that has also allowed to reach of the ratio a=c.

Fig.3. Orientation anisotropy of APB energies (EAPBx10, J/m2) on limits of tetragonal variation.

5. Conclusion.

Both ways in realization of APB algorithm mutually supplement each other. So, if in the first case for PtZn the additional tetragonal distortion (-2 %) is received, in the second case, it is shown, that such distortion gives the simple increase of APB energies in all orientations. It is incorrect result and it is another criterion in the orientation anisotropy analysis of APB energies. The results on additional distortion of a lattice for CuAu are received, but such distortion does not lead to equiprobable occurrence of defects in orientations {hkl}, and it is accompanied by the character change of APB formation in all orientations, except {100}. Energies sharply grow in all these orientations. The phase TiAl is stable and resistable to deformation. It has high specific durability.The realization of the second direction in the given model has added the information, obtained within the framework of tetragonality change for the experimental heat H. A changes range of tetragonal distortions is dilate. The compression and the stretching of a lattice is symmetric concerning given values.

The probability dependence of APB formation from the heat of alloy formation is very strong in some orientations. In alloy PtZn there are {101}, {111}, {210}, in smaller degree- {211}, {212}. In CuAu the given dependence in addition is observed in {100} too. The strong influence of heat H to energetics in orientation {100} is a feature of phase TiAl, in smalle degree-in {210}.

It is necessary to note, that a range of change as a whole for all t in alloy PtZn 8-40 % from the sum of sublimation energies sum of metals-components, for CuAu-1-27%, for TiAl-1.1-8.5%.

References.

1. Baurn N. Defects of crystal lattice. Intermetallic combination (Metallurgy, Moscow, 1970) p. 178.

2. Feng C.R.,.Michel D.J. and Crowe C.R. Philos. Mag. Lett. 61 (1990) 95.

3. Feng C.R.,.Michel D.J., and Crowe C.R. Scripta Metallurgica et Mater.24 (1990) 239.

4. Grinberg B.A. and Sutkina V.I. New methods of hardening of ordered alloys (Metallurgy, Moscow, 1985) p. 176.

5. Girshick A. and Vitek V. Mat. Res. Soc. Symp. Proc. 364 (1995) MRS.

6. Girifalco L.A. and Weizer V.G. Phys. Rev.116 (1959) 68.

7. Kozlov E.V., Dementjev V.M., Kormin N.M. and Shtern D.M. Structures and stability of ordered phases (Tomsk University, Tomsk, 1994) p. 248.

8. Kawabata T. and Izumi O. Philos. Mag. A 55 (1987) 823.

9. Mahapatra R., Girshick A.,.Pope D.P. and Vitek V. Scripta Metallurgica et Mater. 33 (1995) 1921.

10. Popov L.E., Koneva E.A., and Tereshko I.V. Deformation hardening of ordered alloys (Metallurgy, Moscow, 1979) p. 256.

11. Paidar V. Acta Metall.33 (1985) 1803.

12. Shtremelj M.A. Durability of alloys. Defects of lattice (Metallurgy, Moscow, 1982) p. 220.

13. Wang W.K. and Iwasaki H. J.Phys. Chem. Solids.48 (1987) 559.